Case Studies

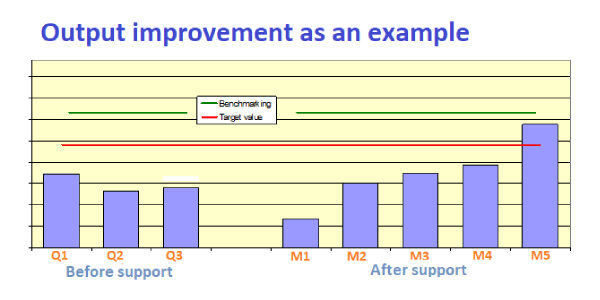

Mission was to improve productivity and quality in one of downstream operation in steel plant, good success was obtained continue for 2 quarters with increasing productivity [+40% in galvanizing, +35% in pickling line and + 15% in cold rolling mill] and output quality standard remarkable achieved compare to benchmarking plant. These results were achieved through process improvement and minor investment.

With technical support through KMP animation to global metal coating plants in order to reduce gap between weak and strong KPI’s, realized financial gain roughly of5 M€ & 9.2 M€ continue for 2 years.

Invented, designed, installed & patented a “New efficient preheating system” for hot dip galvanizing process. After installing this new type of preheating technology in the existing plant, the product quality has considerably improved and zinc metal consumption was subsequently improved by 25 %.

Whether you have a question, concern, we would love to hear from you! Our dedicated customer service team is ready to assist you with any inquiries you may have.